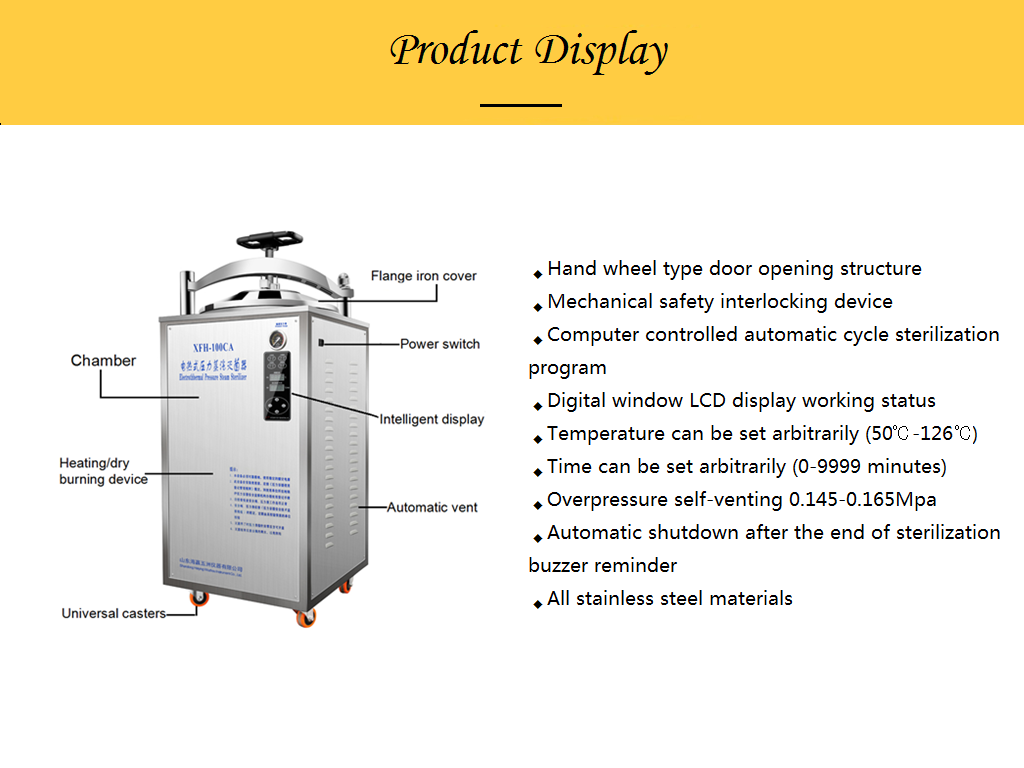

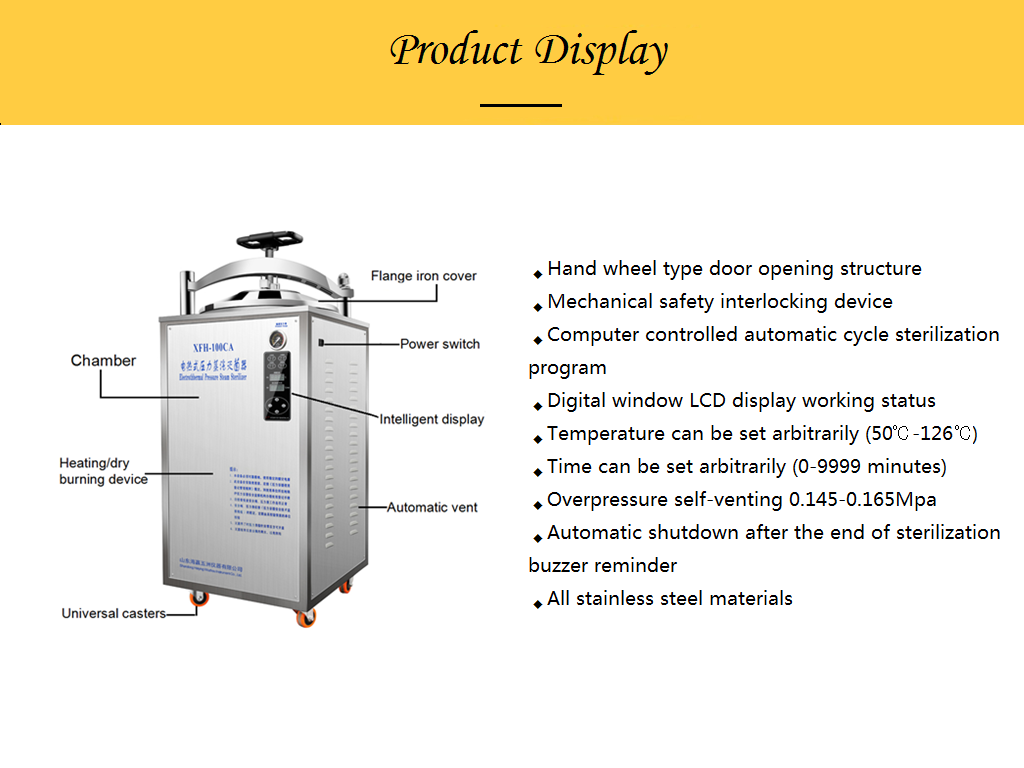

Vertical Autoclave Sterilizer Features:

◆ Auto discharge the cool air, and steam discharging automatically

after sterilization

◆ Automatically shut off with beep reminding after sterilization

◆ The accident protection system

Model | Material | Volume | Power Supply | Output power | Dimension of sterilizing chamber | Net weight | Package Size |

XFH-50CA | All stainless steel | 50L | 220V | 3.5kW | 340 x 525mm | 58Kg | 570 x 570 x 1300mm |

Vertical autoclave sterilizer use and maintenance instructions:

1. Vertical autoclave sterilizer, the operation staff must be in

the correct use of standardized operation, to avoid an accident.

2. should ensure that container of water, high water level can make

the wet dressing, and waste of power supply, water level is too low

will not work properly.

3. began to heat, must be steam feed valve handle in position, make

the cold air inside the container escape, otherwise you will notTo

the disinfection effect of the good.

4. after each terminated after disinfection sterilization must shut

off the power switch.

5. The solution of disinfection sterilization, the solution should

be pumped into the high temperature resistant glass bottles,

injection quantity for the bottle of 34 volume advisable,

application gauze on the bottle, avoid by all means use a stuffy

cork, and the solution bottle placed in a container can hold

solution quantity, in case of a one thousand solution bottle burst

in the process of disinfection sterilization, and other items.

6. after the termination of disinfection vertical autoclave

sterilization, disinfection fungus is a solid objects, but will

bleed valve handle in the vent steam, when the pressure gauge

pointer back to "0" position, can open the container cover, if

disinfection sterilization items solution or medium etc., do not

immediately release the steam, solutions in order to avoid boiling

overflow, cause an accident. Should be shut off the power, after

being pressure gauge pointer back to "0", and open the container

cover.

7. sterilizer after the termination of daily use, strike the sewage

drainage net within the container, the container and erase scale,

improve the quality of disinfection sterilization, as well as

energy saving and service life. If the container has more wipe not

to scale, can use the following solution cleaning scale. With

herself for: 10 kg of water, 1 kg caustic soda, 0.25 kg of kerosene

in container, soak about 1 hour, then wash scale, the final rinse

off with clear water.

8. sealing washer will use day long aging, affect the sealing

effect, should replace the sealing ring at this time.

9. Pressure gauge test at least once a year, if the pressure gauge

pointer back to "0", should be professional maintenance or update,

otherwise it will affect the disinfection effect of the use of

safe.